The solution:

Organized structure and customized solution

DIAM found CUSTOMTOOLS videos from YouTube, contacted the CUSTOMTOOLS team, and started the discussion. One of the reasons DIAM was interested in CUSTOMTOOLS was the ERP Connector included. They were also interested in property management, batch processing, and BOM features.

The DIAM team created a very organized structure in CUSTOMTOOLS and set up ERP integration in place. CUSTOMTOOLS team did also some customization work.

In their solutions:

- The customized project creator tool creates projects, folders, and locations in the servers. Part numbers are generated automatically by combining customer brand or project number, sequence, and suffix.

- CUSTOMTOOLS guides the designer by reducing, e.g., the material options available if the designer is using purchased parts to avoid errors.

- There is a customized structure in CUSTOMTOOLS that matches the structure of ERP. Everything that is visible in CUSTOMTOOLS is also visible in ERP, which reduces the designers’ pain in understanding the ERP system.

- The customized CUSTOMTOOLS batch printing template enables them to ZIP items, even 1 500 parts, with one hit of a button.

- The customized feature lets them filter parts in the assembly based on materials, export the 3D drawings, zip them, and make them easy to share.

- The customized clean-up tool clears unnecessary information from the database, which speeds up the SQL load up and is helpful when people work from several locations.

- Report templates support sustainability and estimating reporting.

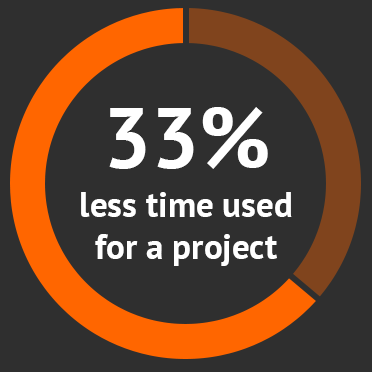

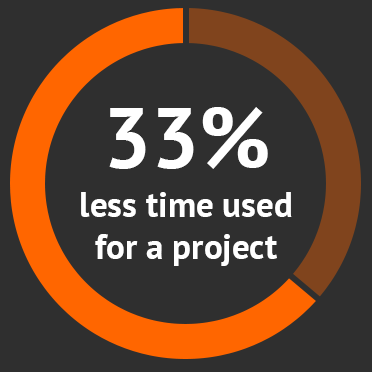

The outcome:

Project delivery time significantly improved due to reduced admin work needs

CUSTOMTOOLS has helped DIAM to save time. In addition, a more guided manner of working has increased efficiency.

Faster delivery is a competitive advantage in an industry that is generally short in time.

If you are interested in learning more about CUSTOMTOOLS or SOLIDWORKS development, you can contact us or download a free demo of CUSTOMTOOLS today!